How To Start Your Own Self-Storage Business

How To Start Your Own Self-Storage Business

The demand for self-storage has been steadily climbing, fueled by life transitions like moving, downsizing, or simply needing extra space. This has turned the self-storage industry into a surprisingly profitable and scalable venture for aspiring entrepreneurs. If you’ve ever considered tapping into this market, you’re in the right place. This guide will walk you through the essential steps to start a successful self-storage business.

1. Research and Planning

Every successful business begins with a solid foundation of research and planning. Before you invest any capital, you need to understand the market you’re entering and create a detailed roadmap for your new venture.

Market Research

Your first task is to analyze the local demand for self-storage. Are residential areas growing? Are businesses in the region expanding? Look for indicators that people need more space than they currently have. Study your potential competitors. What services do they offer? What are their prices? Identifying gaps in the market—such as a lack of climate-controlled units or vehicle storage options—can give you a competitive edge.

It’s also crucial to understand your future customers’ needs. Will you primarily serve residential clients who need to store furniture, or commercial clients who require space for their inventory?

Business Plan

Once you have a handle on the market, it’s time to draft a business plan. This document will be the blueprint for your entire operation. A strong business plan should include:

- Mission Statement: A clear declaration of your business’s purpose and values.

- Target Audience: A detailed profile of the customers you plan to serve.

- Services Offered: A breakdown of the types of storage units and services you will provide.

- Pricing Strategy: A competitive pricing model based on your market research.

- Financial Projections: Realistic forecasts of your startup costs, revenue, and profitability over the first few years.

2. Securing Funding

With a business plan in hand, you can start seeking the capital needed to get your facility off the ground. Startup costs for a self-storage business can be substantial, so it’s essential to have a clear financial picture.

Estimate Startup Costs

Your initial investment will cover several major expenses. These include land acquisition, construction costs, legal fees for permits, and the purchase of essential equipment, such as security systems and management software. Don’t forget to budget for initial marketing campaigns and operational expenses to keep the business running before it becomes profitable.

Funding Options

There are several avenues to choose from when securing funding:

- Personal Savings: Using your own money reduces debt and gives you complete control.

- Bank Loans: Traditional business loans are a common option, especially with a solid business plan.

- SBA Loans: The Small Business Administration offers government-backed loans with favorable terms.

- Investors: Pitching your business to private investors or partners can provide significant capital in exchange for equity.

When approaching lenders or investors, a well-researched business plan and confident pitch are essential to demonstrating your venture’s potential for success.

3. Choosing the Right Location

While location isn’t as crucial in this line of business as it is in others, this is a factor you won’t want to overlook. That’s because the right site can be the difference between a thriving business and one that struggles to attract customers.

Factors to Consider

Visibility and accessibility are key. A facility located near a major road or highway is more likely to catch the eye of potential customers. Proximity to dense residential neighborhoods or commercial districts can also drive consistent demand. Before you get too attached to a property, check local zoning laws to ensure a self-storage facility is permitted.

Site Selection

When evaluating potential properties, think about your long-term goals. Does the site offer room for future expansion? A scalable location allows you to add more units as your business grows, maximizing your investment over time.

4. Designing and Building Your Facility

The design of your facility directly impacts operational efficiency and customer satisfaction. A well-planned layout can maximize your rentable space and provide a secure, convenient experience for your clients.

Facility Layout

Decide on the mix of unit types you will offer. Standard drive-up units are popular, but there might be a high demand for climate-controlled spaces to protect sensitive items. You could also consider specialized storage for vehicles, boats, or RVs. Your layout should allow for easy navigation and efficient use of space.

Construction of the Facility

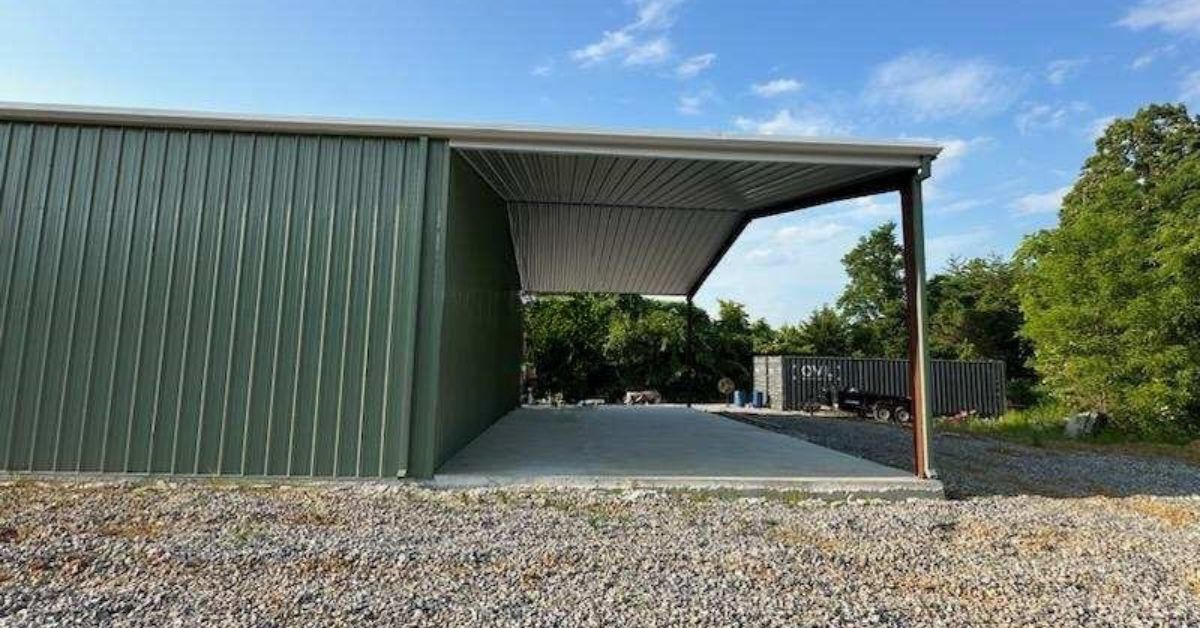

Building a self-storage facility requires working with experienced architects and contractors. They can help you design a functional and cost-effective facility that meets all local building codes. However, if you opt for a metal self-storage building, the construction process will be much faster and easier.

5. Legal and Regulatory Requirements

Starting a business involves navigating a web of legal and regulatory requirements. Addressing these early on will protect you from potential fines and legal issues down the road.

Business Registration

First, choose a business structure. Options like a Limited Liability Company (LLC) or a corporation can protect your personal assets from business liabilities. Once you’ve decided, register your business name with the state and obtain an Employer Identification Number (EIN) from the IRS.

Licenses and Permits

You will likely need various local, state, and federal permits to operate legally. These can include business licenses, occupancy permits, and environmental certifications. It’s also crucial to secure adequate insurance coverage to protect both your business and your customers’ property.

6. Setting Up Operations

With the physical structure in place, it’s time to set up the systems that will run your day-to-day operations smoothly. Setting these right early on will save you a lot of headaches later.

Technology and Software

Modern self-storage facilities rely on management software to handle everything from billing to gate access. Choose a system that offers online booking and payment options to provide a convenient experience for your customers. This technology can also automate many administrative tasks, freeing up your time to focus on other priorities.

Staffing

Determine your staffing needs. You may need a facility manager or lower-level employees to handle customer inquiries, sales, and daily operations. Just make sure you hire employees who are friendly and reliable, and provide them with thorough training on your software and security protocols.

Security Measures

Security is a top priority for customers. That’s why you should install a comprehensive security system that includes surveillance cameras, electronic gate access, and individual unit alarms. A well-lit and secure facility will build trust and attract more clients.

7. Marketing Your Self-Storage Business

Even though you may be ready to open your doors, an essential part of starting your own self-storage business is letting people know you exist. A strategic marketing plan will help you attract your first customers and build a strong brand presence.

Marketing Strategies

A mix of digital and local marketing strategies often works best, so choose the ones you believe will work best for you.

- Digital Marketing: Invest in search engine optimization (SEO) to appear in local search results. Pay-per-click (PPC) advertising and social media marketing can also drive traffic to your website.

- Local Advertising: Distribute flyers in nearby neighborhoods, partner with local moving companies and real estate agents, and participate in community events.

- Promotions: Offer introductory discounts or promotions for new customers to generate initial buzz and fill your units quickly.

Branding

You can follow this up by creating a memorable brand. Choose a business name, logo, and tagline that are professional and easy to remember. A strong brand identity will help you stand out from the competition. Complete this process by establishing a professional website that clearly presents your services, pricing, and location information.