What to Consider When Buying a Prefabricated Steel Building

What to Consider When Buying a Prefabricated Steel Building

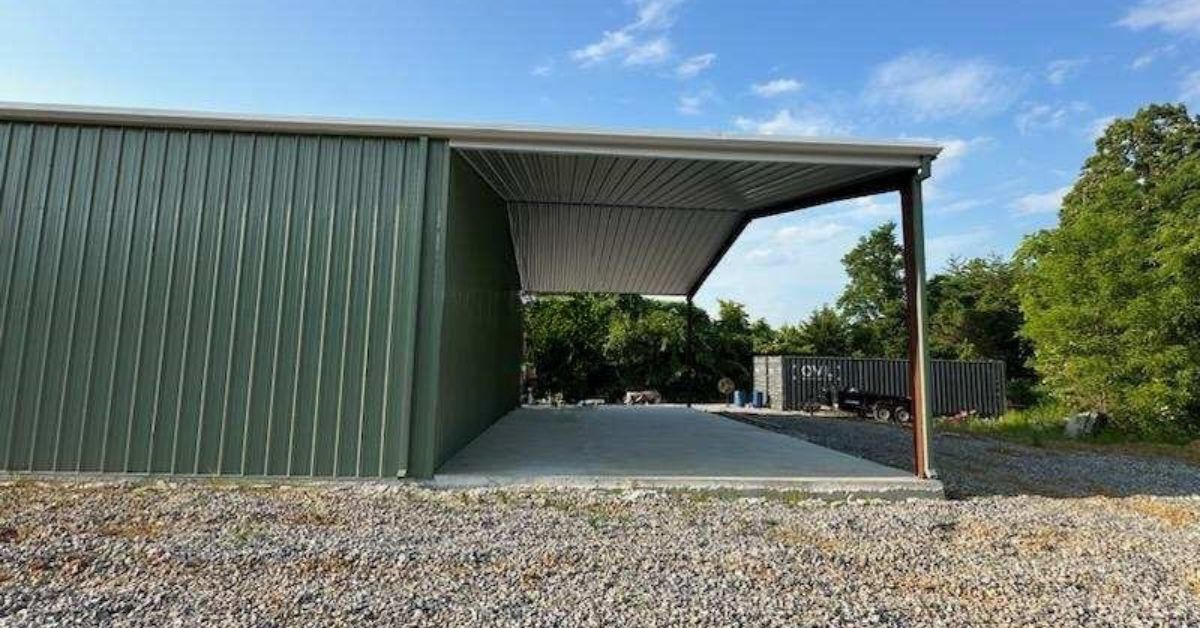

Prefabricated steel buildings have become a popular choice for many businesses and institutions, and for good reason. They offer a winning combination of versatility, cost-effectiveness, and durability that traditional construction often can’t match. From warehouses and workshops to modern office spaces and retail centers, these structures provide flexible and reliable solutions for growing operations.

We understand that investing in a new building is a significant decision. You want to ensure you’re making the right choice for your business’s or institution’s future. This guide is designed to walk you through the key considerations when purchasing a prefabricated steel building in order to help you make an informed decision with confidence.

Your Purpose and Needs

While you definitely know what you plan to use your new building for, have you taken the time to define its more specific purposes? How you use this space will dictate nearly every other decision you make, from its size and layout to specific design features, so now is the time to take note of it.

For instance, a warehouse will need high ceilings and large bay doors for easy access, while an office might prioritize natural light and a specific interior layout to foster collaboration. Take the time to map out your daily operations and long-term goals. This will ensure your new building not only meets your current needs but also supports your business or institution as it grows.

Budget and Cost Factors

Once you have a clear purpose, it’s time to establish a realistic budget. While prefabricated steel buildings are known for being cost-effective, you must first understand all the expenses involved to avoid surprises down the line. Here are the additional factors you should consider:

- Delivery: Shipping costs can vary depending on your location and the size of the building components.

- Installation: Will you hire a professional crew or manage the construction yourself? Labor costs are a significant part of the overall budget.

- Site Preparation: This can include tasks such as clearing land, grading, and pouring a concrete foundation.

- Permits and Inspections: Local municipalities require permits, and their associated fees can add up.

- Utilities: Don’t forget the cost of connecting electricity, water, and sewer lines.

- Interior Finishing: You’ll want to factor in the cost of insulation, drywall, flooring, and electrical work.

Material Quality and Durability

The longevity and resilience of your steel building depend heavily on the quality of the materials used. Not all steel is created equal, so it’s essential to partner with a manufacturer that uses high-grade, durable materials. High-quality steel ensures that your building can withstand harsh weather conditions, including heavy snow, strong winds, and extreme temperatures.

When evaluating a manufacturer, ask about the steel’s gauge and coatings. A lower gauge number indicates thicker, stronger steel. Also, inquire about protective coatings that resist rust and corrosion, which is especially important in humid or coastal climates. Furthermore, ensure that the building design and materials comply with your local building codes and industry standards. A reputable supplier will be able to provide documentation certifying their materials meet these requirements.

Customization Options

One of the main reasons businesses and institutions consider prefabricated steel buildings when purchasing a new structure is their design flexibility. Gone are the days of one-size-fits-all metal sheds. Today, you can customize nearly every aspect of your building to match your operational needs and aesthetic preferences. Think about what features will make your space more functional and efficient. Here are some potential examples:

- Insulation: Proper insulation enhances energy efficiency and regulates interior temperatures, resulting in a comfortable environment year-round.

- Doors and Windows: Choose from a variety of styles and sizes, including overhead doors, roll-up doors, and large windows to increase natural light.

- Interior Layouts: Design a custom floor plan with partition walls to create separate offices, storage areas, or workspaces.

- Exterior Finishes: Select from a wide range of colors and finishes to match your brand’s identity or blend in with the surrounding landscape.

Site Preparation and Location

The location of your building is just as important as the structure itself. Before you finalize your purchase, thoroughly evaluate the proposed installation site. Consider factors like soil type, ground slope, and accessibility for delivery trucks and construction equipment. A geotechnical survey can help determine if the ground is suitable for supporting a heavy steel structure.

Proper site preparation is critical for the stability and longevity of your building. You’ll need to clear the site, level it, and grade it to ensure proper drainage. A professionally poured concrete foundation will help provide a solid base for the structure. Plan for utility connections at this stage to save yourself some time and money later on.

Permits and Regulations

Navigating local zoning laws and building codes can be one of the most challenging parts of any construction project. Before you purchase a building, it’s crucial to research the specific requirements in your area. Zoning regulations may dictate where you can build, the size of the structure, and its intended use.

Building codes, on the other hand, set the standards for construction quality, safety, and materials. To avoid costly delays and fines, verify the compliance of your building plans before starting. Many reputable manufacturers have experience working with local authorities and can assist you in the permitting process. This partnership can be invaluable, ensuring your project meets all legal requirements without a hitch.

Delivery and Installation

Understanding the logistics of delivery and installation is key to a seamless construction process. When your building kit arrives, you’ll need a plan for unloading and staging the components. Ensure your site has sufficient space for large delivery trucks to maneuver.

For installation, you have a few options. Some business or institution owners with construction experience may choose to build the structure themselves to save on labor costs. However, many want to hire a professional crew. While prefabricated buildings are simple to assemble, some prefer the peace of mind that comes with a skilled construction team.

Manufacturer Reputation and Warranty

Finally, the reputation of your manufacturer is a strong indicator of the quality and service you can expect. Take the time to research potential suppliers. Look for companies with a long history of success, positive customer reviews, and a strong portfolio of completed projects. A reputable manufacturer will be transparent, helpful, and committed to the success of your project. Plus, they’ll offer a wide range of options, like metal buildings for churches, for example.

Don’t forget that a solid warranty is another sign of a trustworthy manufacturer. Warranties protect your investment and provide assurance that the company stands behind its products. Look for warranties that cover structural integrity, paint finishes, and other key components. This long-term protection is an essential part of a wise investment.